E Hume 1913 challenge - part 2 of the Foundations Revealed 2015 competition (toile stage)

Posted on

Waists are a negligible quantity

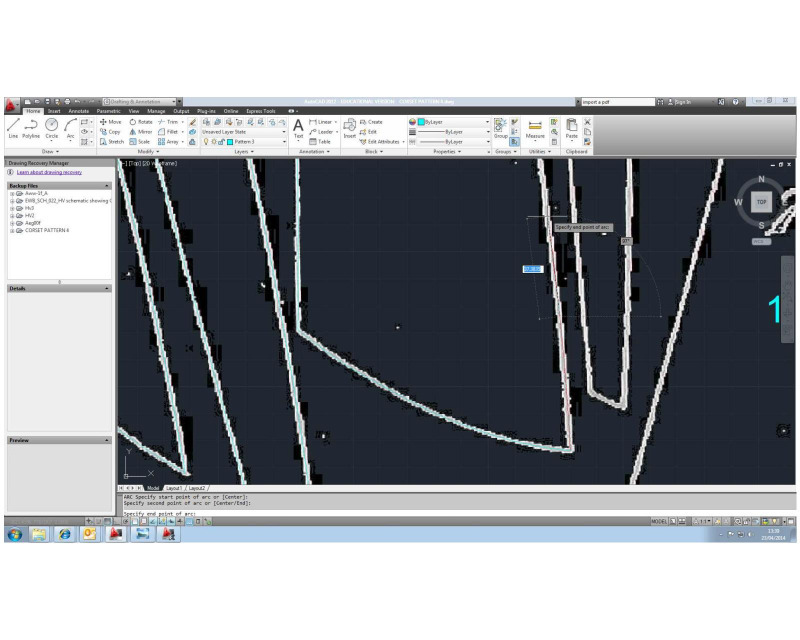

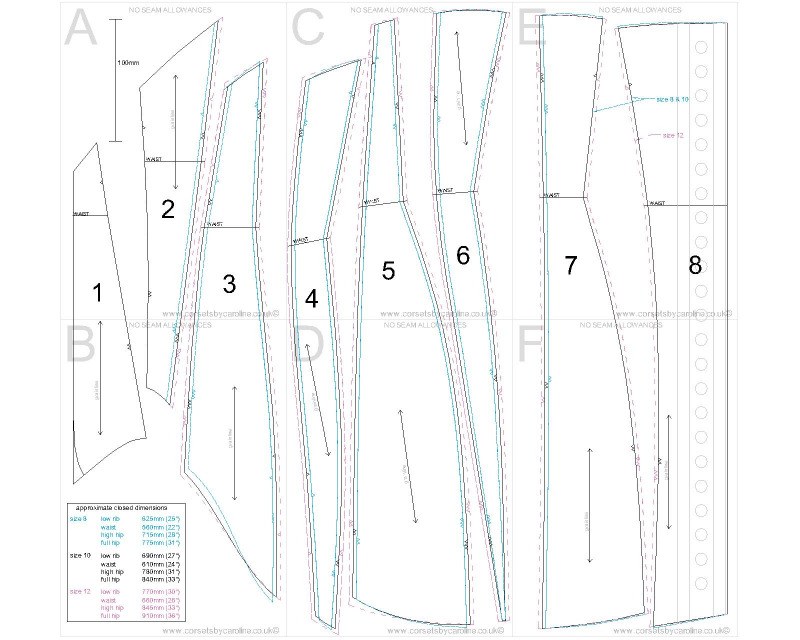

In part one I concentrated on the technical stuff- drafting the pattern in AutoCAD from the pdf supplied by Foundations Revealed. Now I'll make up the toile to check the fit of the corset.

I made up the first toile and amended the fit slightly. It was very low at the font on me – coming only as high as the bottom of my ribcage. I loved the long-line fit. I decided I would make up the corset to this shape but modernise the design somehow. I wanted to be able to see the original shape as Elizabeth Hume intended, but to modernise it to such an extent that I would be able to wear it as an outer garment without suspenders.

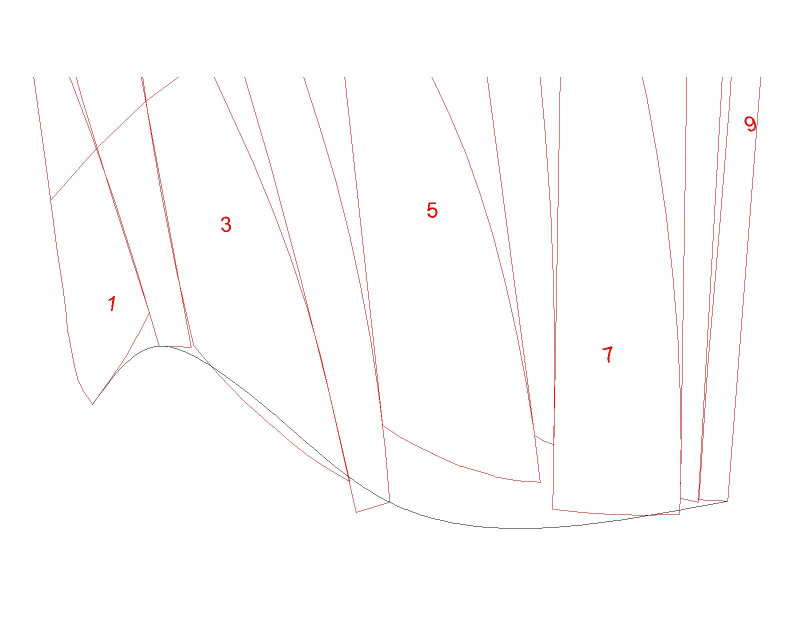

At the first toile stage I marked the waist proper and indicated where the boning would extend to. Obviously to allow the wearer to sit the bones can only extend as far as a standard corset. Here are the photos of my first toile;

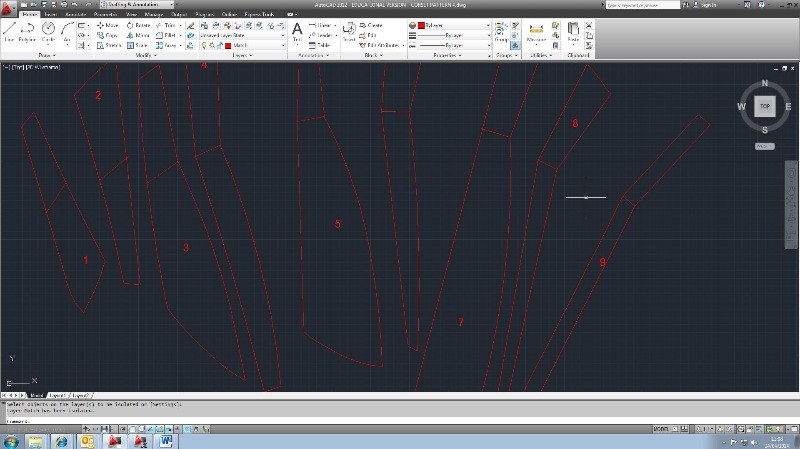

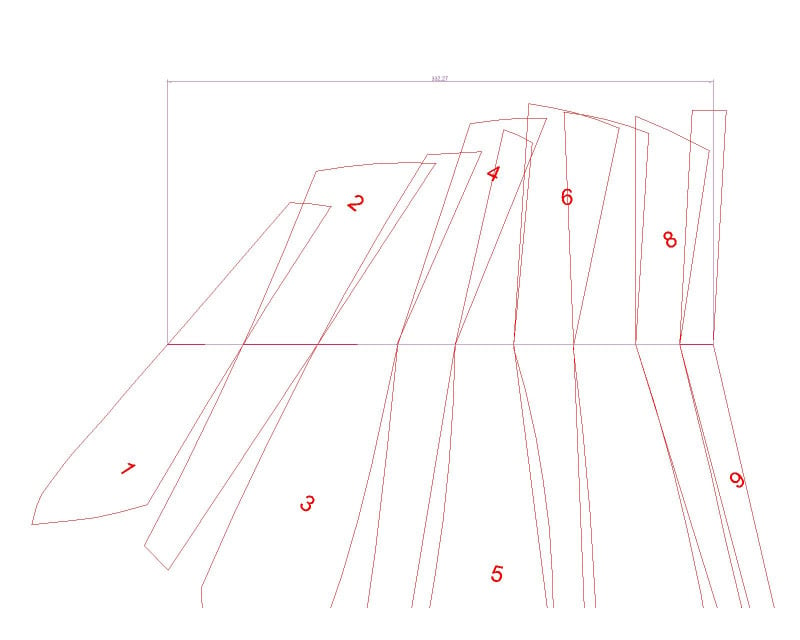

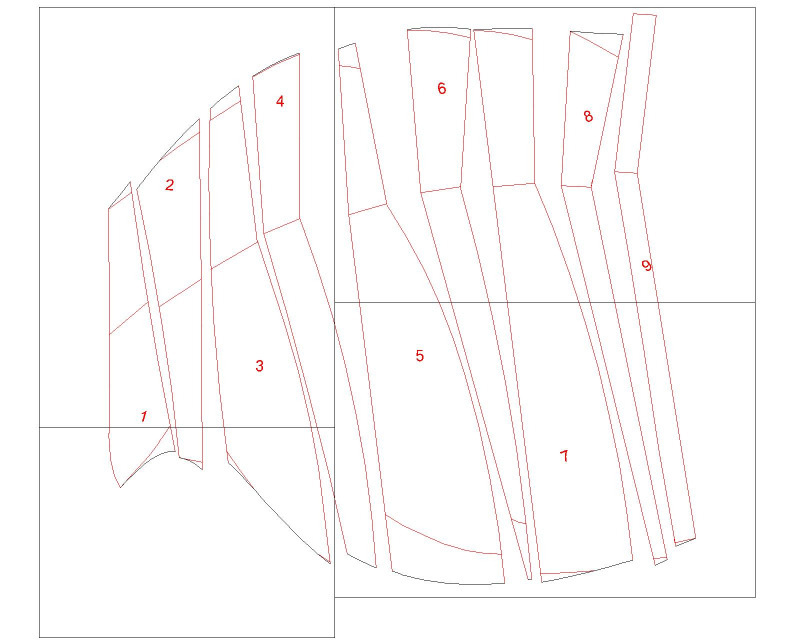

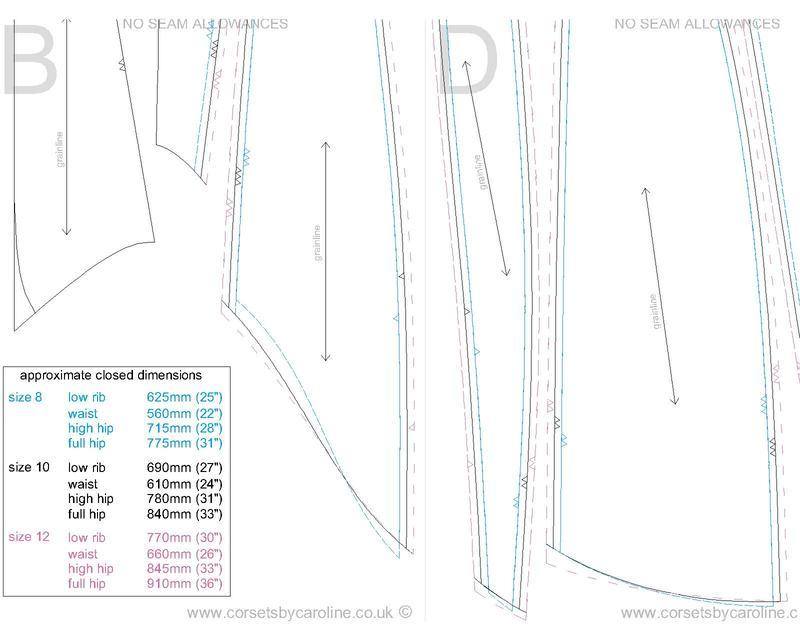

I then made the changes to my AutoCAD pattern. Not strictly true to the original but I didn’t like the odd kink to the rear panels 7 & 8 so I amalgamated these and widened sufficiently to allow for the hardware. Here is the second version of my AutoCAD pattern after the first toile, now incorporating three sizes. I made mine to size 10.

In the next part I will make up the final garment using a base layer of coutil and a 100% wool fashion layer.